Technologies

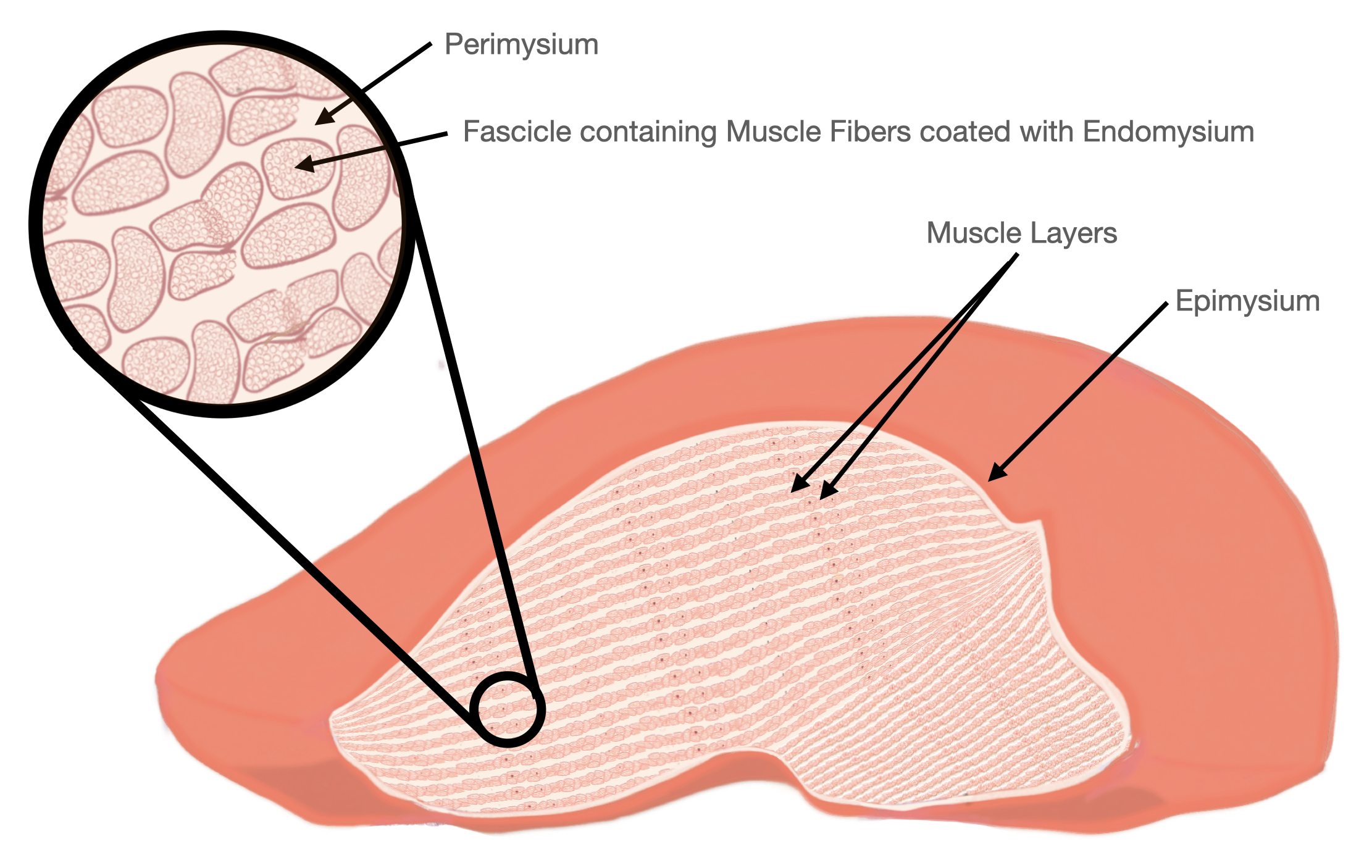

All meats, regardless of species, share a fundamental composition: muscle tissue, connective tissue, and fat. At the core is muscle, structured hierarchically—fibers bundle into fascicles, which layer together to form muscle tissue. This structure varies across species and cuts. Chicken muscle fibers, for example, are typically thinner and longer than those of fish, with greater tensile strength.

The figure below provides a cross-section of a chicken breast, revealing its muscle layers, fascicles, and fibers, along with the connective tissues (epimysium, perimysium, and endomysium).

Schematic of a cross-section of a chicken breast showing its internal hierarchical structures , and a zoom-in into a section of it (left).

When traditional meat is cooked, its texture and flavor undergo precise transformations. Connective tissue softens, fat melts, and complex flavor compounds release, defining meat’s signature aroma.

Replicating this experience using plant materials or cultivated cells presents three key challenges:

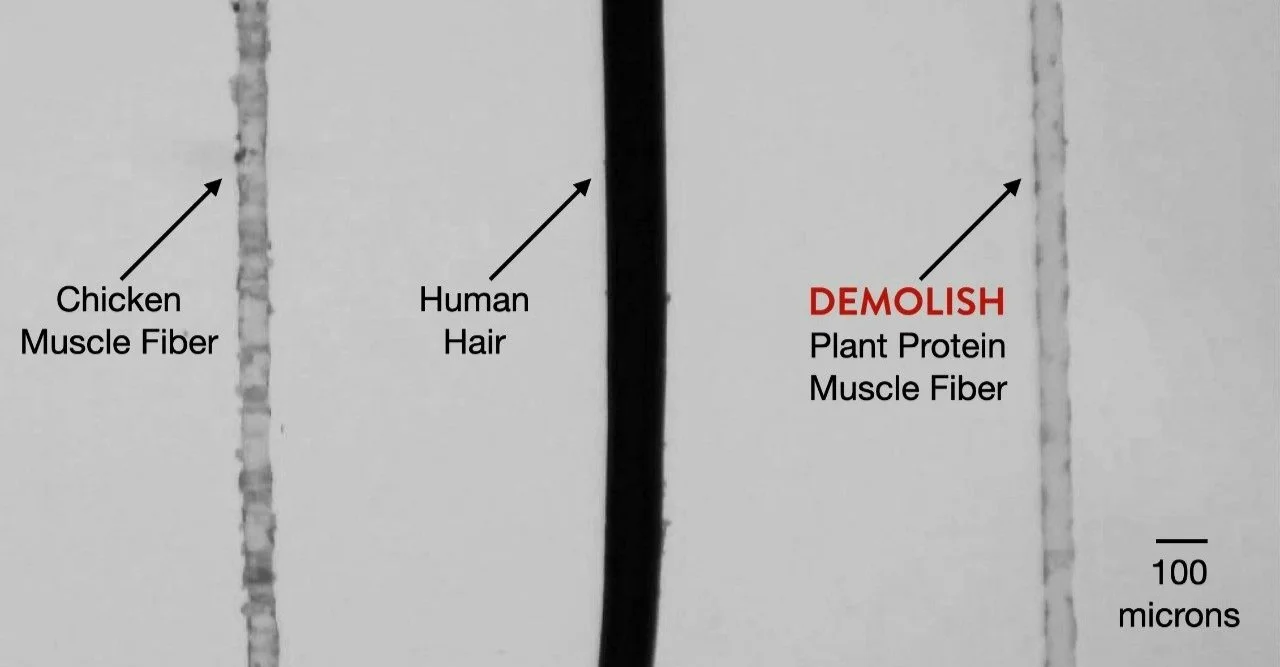

Texture precision – While the human eye can discern objects down to 20 microns, our mouths can detect textural differences as small as 5 microns. Achieving this level of fidelity is essential for realism.

Intramuscle texture variation – Different regions of a muscle have distinct textures, contributing to the complex mouthfeel of whole cuts. Some areas are naturally more tender and juicy, while others are firmer and more fibrous. This variation is crucial for achieving an authentic texture experience.

Heat transformation – Meat undergoes distinct physical changes during cooking. Muscle tissue firms, connective tissue gelatinizes, fat liquefies, and juices release, all of which contribute to the sensory experience of traditional meat.

Demolish Foods' plant-based chicken muscle fiber viewed under a microscope (right), alongside a slaughtered chicken muscle fiber (left) and a strand of human hair (middle).

To solve these challenges, our Gen4 platform leverages several breakthrough technologies:

Protein Chaining enables precise replication of muscle fibers across multiple species, while operating at room temperature to prevent heat-induced protein damage. This ensures that the muscle fibers’ visual, mechanical, and nutritional properties closely mimic conventional meat.

Precision Structuring allows for the recreation of meat’s natural hierarchical organization. By controlling the number of fibers per fascicle, fascicles per layer, and layers per muscle, we can reconstruct complex whole-muscle textures. This process also incorporates connective tissue and fats with tunable properties, ensuring authenticity in every bite.

Thermal Transitioning technology ensures that our cuts cook just like traditional meat—textures evolve, fat melts, juices release, and connective tissue softens at the right temperatures, achieving an indistinguishable culinary experience.

Not only does Gen4 set a new standard for technical accuracy, it also offers incredible nutrition with scalable production efficiency:

Clean Label: Our plant-based whole cuts are gluten-free, non-GMO, and crafted with eight natural ingredients, matching conventional meat in protein, fat, sodium, and calories without compromise.

Complete Whole-Cut Replication: Gen4 is the first fully integrated platform that replicates every perceptible component of conventional meat, bridging the gap between technological innovation and commercial viability.

Scalable Production and Cost Optimization: Achieving a 6x boost in production capacity and a 35% reduction in operational costs, Gen4 leverages multi-vendor ingredient flexibility to enhance supply chain resilience while upholding high product quality.